Cleanroom Services Checklist

There are many specifications and factors you need to take into account before building a brand new cleanroom.

That's exactly why a checklist is important before you make the investment. Cleanroom services involve a lot of manufacturing, research and development.

First, determine which class, regulation or guideline you must comply with.

Then, be sure to have some type of layout or sketch of your floor plan to properly determine emergency exits, mechanical rooms, etc.

Other important aspects of a cleanroom services checklist include deciding what you will be doing in the room, which ISO class you must comply with, what are the dimensions of the room, and many more.

How Much Does a Cleanroom Cost Per Square Foot?

The price per square foot is important when comparing options because it changes a lot depending on the type of cleanroom services needed.

The price can vary from less than $100 to more than $1,000 per square foot. It’s difficult to give an exact answer because calculations need to be done.

Many companies may even add extras onto the cleanroom to up the price, but take careful consideration into both what you need and what you can afford.

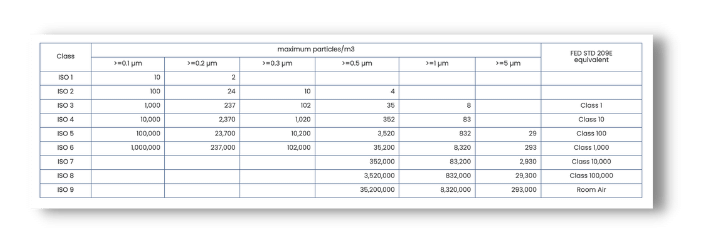

Cleanroom classes are based on the number and size of particles allowed per volume of air.

For example, a Class 10,000 cleanroom would have less than 10,000 particles per cubic foot. With a minimum of 45 to 60 air changes per hour.

Smaller cleanrooms

The bigger the room, the lower the cost per square foot.

With that said, according to ISO 14644-1 cleanroom standards, a class 10 or 100 cleanroom would be considered small. These require larger air changes per minute and filter coverage percentage.

Medium-sized cleanrooms

For these cleanroom standards, a cover or aluminum base channel is an appropriate flooring base.

Larger cleanrooms

They require modular or drywall coverings and sheet vinyl floor coverings.

What is Required for a Certified Cleanroom?

According to Good Manufacturing Practices, “compliant classrooms require full flush design, covered corners, monitoring systems, airlocks'' and much more (cleanroomtechnology.com).

But there are three most important aspects of a cleanroom.

The first is that the internal surfaces must all be “smooth and impervious”.

The second is the control and quality of the air throughout the room, keeping airborne contaminants out.

The final aspect is the way the cleanroom is operated and the type of staff working in the facility, which must all be taken into account when choosing cleanroom services.

Surfaces

GMP compliance requires that surfaces in a cleanroom don’t create contamination upon themselves.

Meaning, no dust, peeling, flaking of any kind that allows microorganisms to enter the atmosphere.

Surfaces also have to be easy to clean, without any ledges. They are rigid, won’t crease, shatter, or be damaged easily.

Air flow

Particles tend to float around and slowly settle.

Basically, a good cleanroom should provide filtered air that circulates often enough to flush out the particles in the facility.

Employee access

Strictly controlling access of employees in and out of the cleanroom reduces the risk of airborne contaminants.

Most protocols make sure that only trained personnel enter the room, limiting the number. Even trained employees end up being the most significant cause of any contamination.

Understand the Cleanroom Classes and Standards

Cleanroom classes tend to be the most confusing part when choosing from different cleanroom services.

It’s important to understand cleanroom standards so you can figure out which class will work best for your needs.

Learning how cleanrooms are measured by inspectors will help you make an informed decision that’s cost-effective and also within the standards measured by federal agencies.

ISO 14644-1 cleanroom standards

ISO stands for the International Organization for Standardization.

These are essentially formulas that describe the best way of doing something, commonly agreed upon by experts around the world.

Specifically, ISO 14644-1 determines the best practices for air cleanliness in regards to cleanroom services.

Inspectors use light scattering airborne particle counters (LSAPC) to determine the concentration of airborne particles in the air.

Depending on the maximum particles/m3, ISO will determine the type of certified cleanroom needed for the facility.

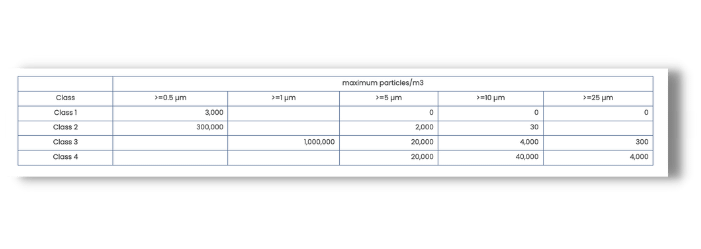

BS 5295 cleanroom standards

A measurement of the particle size range in the room helps determine which class is needed for specific cleanroom services, ranked from C - M.

The British Standard also identifies three states of operation for a cleanroom:

- The first is “as built”, which is a room on completion before employees move in.

- The second is “unmanned”, which is operational but not currently in use.

- And finally, there’s “manned”, which is in full operational use.

Make Your Cleanroom Services Decision Easy

As you can see, there is a lot to take into account when asking how much does a cleanroom cost.

When creating a checklist, you must think about the class and regulation you have to comply with before determining how much you'd have to pay per square foot.

There are different cleanroom sizes based on ISO standards, ranging from class 10 - 100,000.

Surfaces, air flow, and employee access are three criteria needed to take into account when choosing your cleanroom.

So long as you become somewhat knowledgable about ISO 14644-1 Standards, you will have a clearer picture about what cleanroom will best suit your needs.

But you don’t have to do this alone so get help handling your cleanroom services. Whether it’s testing, monitoring, or classes to understand government standards, find a quality partner that you can trust.

Need Our Help? Fill Out a Service Request Today!

We're here to assist you with all your needs. Please complete our service request form to ensure we provide the best possible service.

It's quick and easy—tell us a little about your request, and our team will reply promptly. We look forward to serving you!

Blog Contact Page

We will get back to you as soon as possible.

Please try again later.

Interested in Working with

Sure-BioChem Laboratories

All Rights Reserved | Sure-BioChem Laboratories | Terms & Conditions